“Tin whiskers” is not an imaginative, fanciful term for some aspect of electronics manufacturing.Tin whiskers are real, and they pose a serious problem for electronics of all types. Tin whiskers can could cause short circuits. The switch to alternative solders (away from traditional tin+lead solder) in order to achieve RoHS compliance has created some challenges for the semiconductor industry, especially tin whiskers.

Understanding and mitigating tin whiskers article says that tin whiskers are almost invisible to the human eye and are 10 to 100 times thinner than a human hair. They can bridge fairly large distances between electrical device leads, and in so doing, can short out the conductors. They can grow fairly rapidly; incubation can range from days to years.

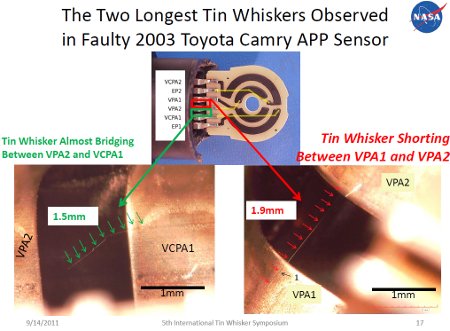

Toyota has had problems with uncontrolled acceleration. Earlier report have said that the acceleration problems that led to the recall of nearly eight million Toyota cars and trucks in 2009 and 2010 were mechanical. Yet some believe that the issue goes beyond the floor mats and some new material on that has just surfaced. Toyota accelerations revisited—hanging by a (tin) whisker article tells that a NASA paper delivered at the International Tin Whisker Symposium last year reported on tin whisker growth in Toyota accelerator pedal position sensors that could lead to unintended acceleration. The whiskers were found in a “failed” sensor from a 2003 Camry and at least two other similar units that did not malfunction. The NASA paper gives further insight by detailing tin whisker physical behavior as well as outlining guidelines and methods of detecting whiskers.

Understanding and mitigating tin whiskers paper tells that tin whiskers are real, and they pose a serious problem for electronics of all types. Connectors, passive and active components, switches, and relays now must all be lead-free, and the switch to alternative solders in order to achieve RoHS compliance has created some challenges for the semiconductor industry, especially tin whiskers. Pure, tin-plated electronics have become ubiquitous over just the past five years. When used as a finish material for electronic components, pure tin can spontaneously grow conductive whiskers.

When a whisker grows between two conductors, the whisker usually fuses (disappears), creating a momentary short circuit. In some cases the whisker forms a conductive path, creating false signals at an incorrect location. In very rare cases, rather than disappearing like a fuse link, the whisker can instead form a conductive plasma.

Because the electronics industry does not really know what causes tin whiskers, cannot predict their appearance other than to say whiskers are likely to form on pure tin. Also higher the altitude, the more rapid the whisker formation.

Here are some suggestions for reducing the risk of tin whiskers:

1. Do not use pure tin. Studies have shown that alloying tin with a second metal reduces the propensity for whisker growth. (minimum of 3% lead by weight is acceptable)

2. Do not rely on the order paperwork. Use x-ray fluorescence (XRF) to verify finish on all critical parts.

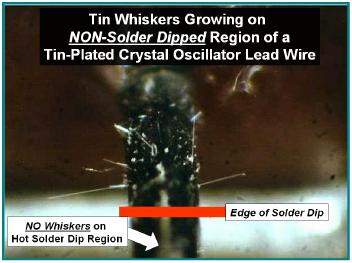

3. Refinish a pure tin-finished part with a hot-solder dip. Stripping and replating is a recommended approach and is a service offered by some of the original part manufacturers.

4. Use some type of encapsulation or conformal coating. Uralane 5750 conformal can provide some benefit by reducing the growth rate, but tin whiskers can grow through conformal coating.

The shift away from lead solder presents risks for high-reliability applications, particularly in the form of tin whiskers on tin-containing finishes. When a tin-bearing finish is used, conformal coatings have been somewhat effective in fighting this problem. Because of the potentially dangerous and unpredictable risks of pure tin, it is not presently used in medical devices.

NASA has lost satellites due tin whisker. NASA Tin Whisker (and Other Metal Whisker) Homepage has more details on that. Tin Whiskers in Electronics Components white paper from Tyco Electronics is also good reading with lots of pictures.

7 Comments

Tomi Engdahl says:

NASA engineers solve device malfunction mystery onboard Saturn-tracking spacecraft

http://www2.electronicproducts.com/NASA_engineers_solve_device_malfunction_mystery_onboard_Saturn_tracking_spacecraft-article-fajb_nana_cassini_march2012-html.aspx

The Cassini spacecraft’s plasma spectrometer, responsible for measuring the energy levels of electrons and protons, is back up and running after NASA engineers spent nine months troubleshooting an electrical problem with it.

The spectrometer was turned off last June after reports showed fluctuating voltage.

After months of investigating the matter, it was discovered that the tin plating on the spacecraft’s electronics components had grown “whiskers.” While very small (less than the diameter of human hair), they were still big enough to contact another conducting surface. This, in turn, caused the device to short out.

Researchers aren’t exactly sure why this phenomenon occurs, but they now know that “tin whiskers” can occur both in space and here on Earth.

“We can’t do anything about the tin whiskers, but the research showed that the whiskers could not carry enough current to cause harm to the spacecraft. So we believe we can live with them.”

Tomi Engdahl says:

Tin Whiskers Again Cited as Potential Problem for Toyotas

http://www.designnews.com/document.asp?doc_id=247907&cid=NL_UBM+Electronics

The debate over the role of tin whiskers in Toyota’s unintended acceleration case has returned, and government administrators are expected to answer more questions on the subject this week.

Even after the National Highway Traffic Safety Administration (NHTSA) declared in 2011 that there was no electronic cause for Toyota’s problems, the debate had quietly continued. It rose to prominence again this month, when a US senator stepped in.

“Recently, whistleblowers have provided my office with information, supported by documentation, which raises concerns that the scope of the NHTSA and NASA investigations may have been too narrow,” Sen. Charles E. Grassley (R-IA) wrote in a letter

Tin whiskers — small metal dendrites that sometimes form on electroplated tin — are an important topic for design engineers, because they can cause short circuits and arcing in electrical equipment. In Toyota’s case, tin whiskers were considered a potential culprit in the “unintended acceleration” claims that grabbed headlines three years ago.

Tomi Engdahl says:

The Electrostatic Theory of Metal Whiskers

http://hackaday.com/2014/05/27/the-electrostatic-theory-of-metal-whiskers/

Thanks to that wonderful ROHS stuff the EU passed more than a decade ago, we should be seeing a few high-profile failures of electronic components due to tin whiskers. These tiny hair-like extrusions of metal found most commonly in lead-free solder have destroyed billion dollar satellites and shut down nuclear reactors, despite no one knowing exactly how these whiskers form. Now there’s a new theory of metal whisker formation (abstract, unless you have access to APS) that actually has predictive power.

[V. G. Karpov] from the University of Toledo suggest these whiskers are formed by differences in charge induced by metallurgical anomalies – contamination, differences in the grain of the solder, and oxides.

The theory of whisker growth is generally consistent with observed rates of whisker growth and other properties.

Tomi Engdahl says:

Synopsis: Growing Whiskers

http://physics.aps.org/synopsis-for/10.1103/PhysRevApplied.1.044001

Various metals widely used in electronics, such as tin and zinc, often show hairlike protrusions on their surfaces. These “whiskers” can be responsible for current leakage and short circuits in electronic equipment, causing billion-dollar losses in the auto, aviation, and space industries. But the formation mechanism of whiskers has remained a mystery for over 60 years and researchers have been unable to provide even order-of-magnitude predictions of whisker parameters.

Now, Victor Karpov at the University of Toledo, Ohio, has proposed a theory that provides, for the first time, quantitative estimates of whisker nucleation, growth rates, and length distributions.

Karpov’s analysis delivers estimates of whisker parameters that are generally consistent with observations

more reliable models of whisker evolution will be useful not only for microelectronic technologies, but also for large-area photovoltaic

Tomi Engdahl says:

Improve device reliability via PCB cleanliness

http://www.edn.com/design/pc-board/4437935/Improve-device-reliability-via-PCB-cleanliness?_mc=NL_EDN_EDT_EDN_consumerelectronics_20141217&cid=NL_EDN_EDT_EDN_consumerelectronics_20141217&elq=90cda48b5c8b49989e03f6ee38c4c3ce&elqCampaignId=20763

Component manufacturers are continually developing new and smaller packages for components that are mere fractions of a millimeter and have board to component clearances of less than a mil. Pick and place machines have new accessories that allow placement of these almost invisible parts. Components are placed extremely close together. How do you effectively clean under something so small?

No-lead solder is a relatively recent legislated fact of life that necessitated new solder, new fluxes, higher temperatures, and new solder processing equipment. Many new approaches, alloys, chemicals, and soldering processes have been developed to address these issues. Tin whisker problems also increased dramatically. Time-delayed effects, however, often will not show up until a product is out the door and has been in service for even a year or two. The pace of product development covers up some of these time-delayed issues when products are routinely discarded for newer models. For products such as mobile phones, problems don’t often show up because comparatively few people are using a mobile phone that is more than 2-3 years old.

Tomi Engdahl says:

Tin Whiskers Brewing Company: Engineered to Perfection

http://www.eetimes.com/author.asp?section_id=36&doc_id=1326085&

Short Circuit Stout, Wheatstone Bridge, and Ampere Amber are three of the craft beers on tap at a micro-brewery owned by three—maybe you guessed who already?–electrical engineers.

Tomi Engdahl says:

Runaway acceleration

https://www.edn.com/electronics-blogs/living-analog/4461903/Runaway-acceleration