OpenSCAD is a free software for creating solid 3D CAD objects. It is open source software that is available for Linux/UNIX, MS Windows and Mac OS X – and also a version that runs online in browser. After quick testing it looks like OpenSCAD is a really wonderful tool for 3D modeling. While it doesn’t have the traditional graphical interface of AutoCAD – it’s basically a programming language for 3D models – OpenSCAD is able to create very complex parts with only a few lines of code. OpenSCAD allows for two types of modeling – constructive solid geometry, or taking 3D primitives and stretching, scaling, and intersecting them to create a 3D shape, or extrusion from a 2D outline. It should be sitable for making desings for 3D printing as quite a few RepRap parts were designed in OpenSCAD and Makerbot 3D printer maker has OpenSCAD tutorials for this in mind.

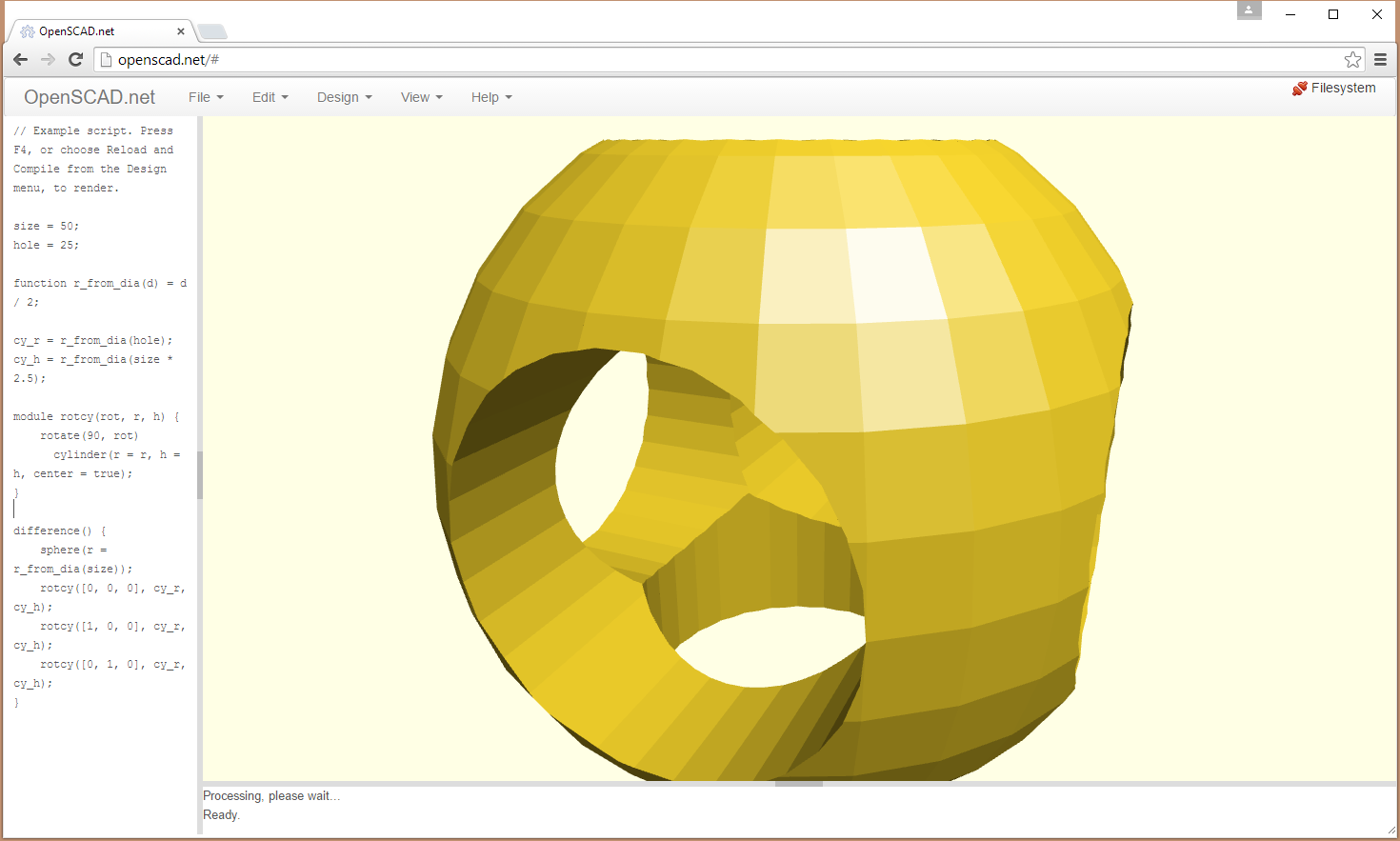

If you want to start experimenting with OpenSCAD parts in your browser. There are two alternatives for this. OpenSCAD.net offers one online version of OpenSCAD that runs nicely at least on Chrome browser (failed to work properly in Firefox for me). It is a nice playground to test OpenSCAD.

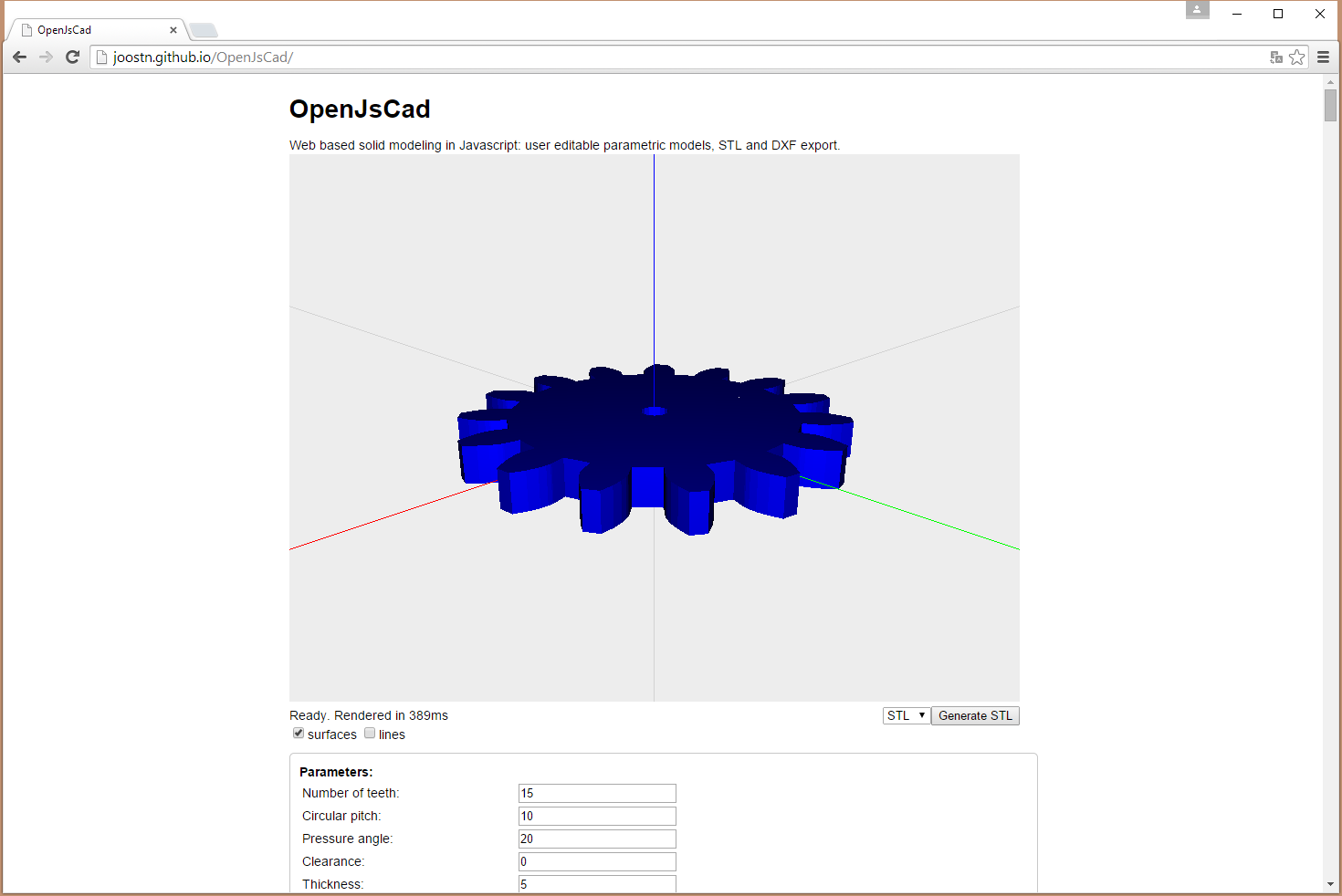

OpenJsCad is a 2D and 3D modeling tool similar to OpenSCAD, but web based and using Javascript language.

3D solids can be exported as STL files, 2D areas can be exported in a DXF file. OpenJsCAD is written entirely in Javascript and able to be embedded in a web page. To build your own models, create a .jscad file with your javascript code and parse the file using the OpenJsCad parser.

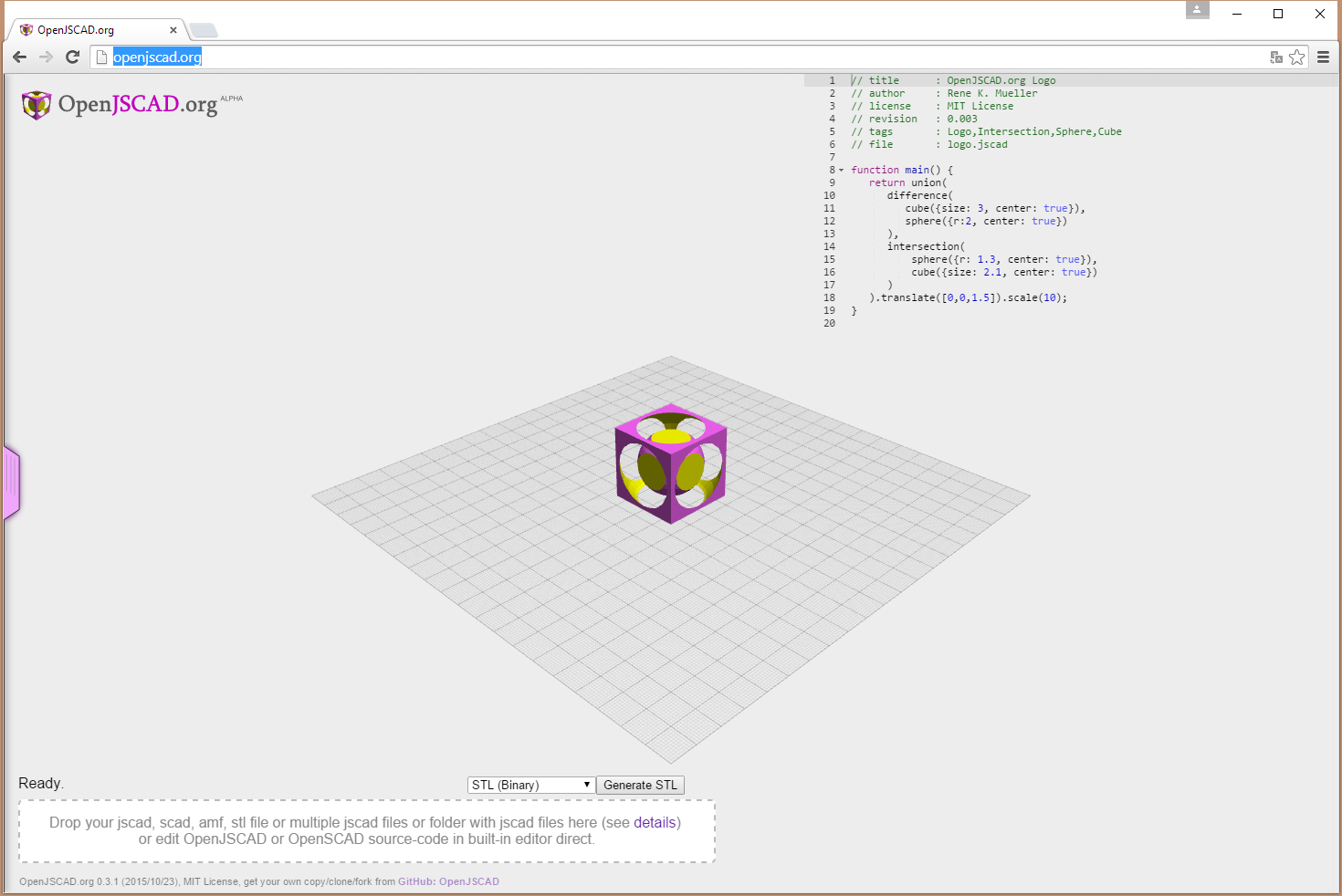

There is an alpha version of the software on-line at openjscad.org. It is is intended to become a Javascript based alternative to OpenSCAD, for 3D solid modeling.

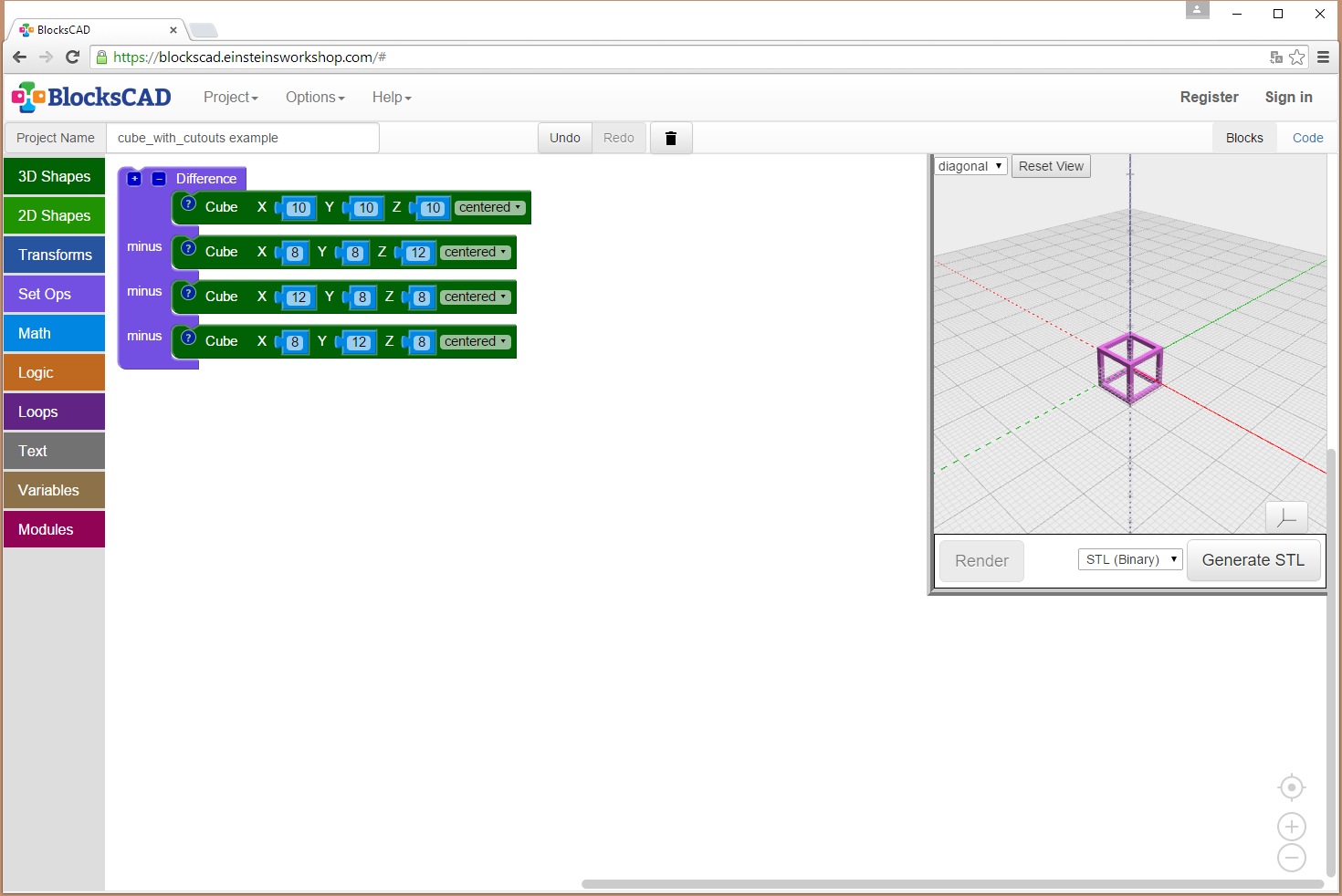

Does coding your 3D objects, while quite easy, still look too complicated to get started. There are also some alternatives that are even easier to get started. BlocksCAD is Browser-Based 3D Modeling that Teaches You CAD. MIT has come up with a new block-based educational tool called BlocksCAD. BlocksCAD is essentially Scratch combined with OpenSCAD and allows the user to use blocks (similar to Scratch) to build a 3D model. With this tool it’s possible to avoid model code syntax issues but still develop 3D models. You just make model by moving blocks, and get a 3D model and OpenSCAD code as result. You can use the tool online at blockscad.einsteinsworkshop.com

For ideas on other 3D modeling tools, check out also Scratch Your Itch for 3D Modeling with BeetleBlocks, Learn 3D Modeling in Your Browser and Development Tools of the Prop-Making World articles.

114 Comments

Tomi Engdahl says:

Bit Of OpenSCAD Code Caps Off Wiremold

https://hackaday.com/2024/06/23/bit-of-openscad-code-caps-off-wiremold/

Wiremold is great stuff — it’s relatively cheap, easy to work with, and offers all sorts of adapters and angle pieces which take the hassle out of running (and hiding) wires. But [Dr. Gerg] found a shortcoming of this otherwise very flexible product: since each run is intended to start and end in a surface mounted box, he couldn’t find an end cap that would let him close off a section.

The solution? A desktop 3D printer and a chunk of OpenSCAD code telling it what to extrude. When you break it down, the Wiremold profile is fairly straightforward, and can be easily described with geometric primitives. A handful of cylinders, a cube or two, tie it all together with the hull() function, and you’re there.

https://www.drgerg.com/wiremold-end-plug.html

Tomi Engdahl says:

https://hackaday.com/2024/07/01/freecad-foray-shells-for-all-our-pcbs/

Tomi Engdahl says:

The End Of Ondsel And Reflecting On The Commercial Prospects For FreeCAD

https://hackaday.com/2024/11/12/the-end-of-ondsel-and-reflecting-on-the-commercial-prospects-for-freecad/

Within the world of CAD there are the well-known and more niche big commercial players and there are projects like FreeCAD that seek to bring a OSS solution to the CAD world. As with other OSS projects like the GIMP, these OSS takes on commercial software do not always follow established user interactions (UX), which is where Ondsel sought to bridge the gap by giving commercial CAD users a more accessible FreeCAD experience. This effort is now however at an end, with a blog post by Ondsel core team member [Brad Collette] providing the details.

The idea of commercializing OSS is by no means novel, as this is what Red Hat and many others have done for decades now.

As also discussed on the FreeCAD forum, the Ondsel codebase will likely be at least partially merged into the FreeCAD code, ending for now the prospect of FreeCAD playing in the big leagues with the likes of AutoCAD.

https://ondsel.com/blog/goodbye/

While we have failed to build a sustainable commercial business around FreeCAD, we have accomplished many things.

Ondsel repository – merging Ondsel into FreeCAD, or merging FreeCAD into Ondsel and call Ondsel the new FreeCAD?

https://forum.freecad.org/viewtopic.php?t=92024

Tomi Engdahl says:

https://9to5linux.com/freecad-1-0-open-source-3d-parametric-modeler-released-heres-whats-new

Tomi Engdahl says:

2024 Brought Even More Customization To Boxes.py

https://hackaday.com/2025/01/01/2024-brought-even-more-customization-to-boxes-py/

Tomi Engdahl says:

https://etn.fi/index.php/13-news/17127-digikey-laajentaa-ladattavien-cad-mallien

Tomi Engdahl says:

https://hackaday.com/2025/02/08/software-in-progress/

Tomi Engdahl says:

Boxes.py

Cut out boxes and other stuff with a laser cutter

https://hackaday.io/project/10649-boxespy

Tomi Engdahl says:

https://hackaday.com/2025/02/17/parametric-design-process-produces-unique-speakers/

The bulk of the speakers were designed with OpenSCAD, with the parametric design allowing for easy adjustments to accommodate different drivers and enclosure volumes. A number of the panels of the speakers are curved as well, which is more difficult with traditional speaker materials like MDF but much easier with this 3D printed design.

Tomi Engdahl says:

https://hackaday.com/2025/02/18/belfry-openscad-library-bosl2-brings-useful-parts-and-tools-aplenty/

Tomi Engdahl says:

CaDoodle: Doodle in CAD!

A drag-and-drop CAD package that is an open source, local application alternative to TinkerCAD

https://hackaday.io/project/202791-cadoodle-doodle-in-cad

CaDoodle is a local drag-and-drop CAD application for Linux (Arm,x86), WIndows (X86), and Mac (Arm,x86) and ChromeOS. Users models are stored locally, and the application runs entirely locally. CaDoodle has a drag and drop interface that is cross-trainable with TinkerCAD.

1. Drag and drop shape

2. Group and ungroup

3. Solid and Hole status

4. Undo of operations

5. Stretch and move handles

6. Library of examples

7. Nearest Surface snappping

Key Improvements over Tinkercad

* Boolean operations such as Hull, Intersect, and XOR

* Inkscape as the sketching tool is much more powerful sketching tool

* Blender integration brings Sculpted elements easily into CaDoodle

* OpenSCAD scripts supported as file sources

* BowlerStudio scripts supported

* Gridfinity bins a 1st class object

* FreeCAD models supported as source models

* Export directly to STL, SVG, OBJ, Blender, FreeCAD

Download the installers here: https://cadoodlecad.com/

Tomi Engdahl says:

typeCAD

programmatically create hardware

https://hackaday.io/project/202664-typecad

View Gallery

Public Chat

276

0

45

1

Team (1)

typecadtypecad

Join this project’s team

Website

Reddit

Software

ongoing project

kicad schematic-as-code typescript typecad

This project was created on 03/17/2025 and last updated 10 hours ago.

Description

TypeScript + KiCAD = typeCAD

- Write TypeScript code and build it into a KiCAD project

- Use all the normal software tools, but now for hardware

- Package your code into small packages

- Quickly combine known-working packages into larger projects

Instead of using the KiCAD schematic editor, you write code and build it into a KiCAD schematic.

typeCAD uses TypeScript. You don’t need extensive knowledge of TypeScript to get started.

If you’re familiar with any programming language, you can pick up the basics of TypeScript pretty quickly.

KiCAD

The normal flow in KiCAD is:

1. Create a project and schematic

2. Add components

3. Make connections

4. Lay out the board

typeCAD

typeCAD replaces steps 1-3. Instead of clicking and dragging to place components and make connections, TypeScript code is used.

This is how a schematic is created.

import { Schematic } from ‘@typecad/typecad’;

let typecad = new Schematic(‘typecad’);

typecad.create();

That code will create a KiCAD netlist named `typecad.net`, which you can then import into a KiCAD PCB file. No schematic file is created because it’s not needed.

Tomi Engdahl says:

Open Source CAD In The Browser

https://hackaday.com/2025/06/12/open-source-cad-in-the-browser/

Some people love tools in their browsers. Others hate them. We certainly do like to see just how far people can push the browser and version 0.6 of CHILI3D, a browser-based CAD program, certainly pushes.

The project’s GitHub repository shows an impressive slate of features, but also notes that things are changing as this is alpha software. The CAD kernel is a common one brought in via WebAssembly, so there shouldn’t be many simple bugs involving geometry.

https://chili3d.com/

https://github.com/xiangechen/chili3d

Tomi Engdahl says:

We’ve seen a number of browser-based tools that do some kind of CAD. CADmium is a recent entry into the list. Or, stick with OpenSCAD. We sometimes go low-tech for schematics.

https://hackaday.com/2016/12/24/open-source-parametric-cad-in-your-browser/

https://hackaday.com/2022/03/14/the-noble-effort-to-put-openscad-in-the-browser/

https://hackaday.com/2015/10/05/the-worst-cad-package-ever-is-still-handy/