It is pretty easy to do soldering ….Apply some flux, Heat the surface and apply solder .But when it comes to soldering SMD components it requires a little bit of skill and some tools and accessories. Industries use re-flow ovens with temperature profile Control to mass produce circuit boards. If you don’t have re-flow oven, there are also DIY alternatives.

One alternative is hot plate. Place all the surface mount components and placed the Board on the Hot Plate. Turn On the hot plate and wait until the Solder paste melts and take out the board immediately after melt-down of solder paste. The Solder paste melts somewhere around 180 degree Celsius to 220 degree Celsius. Because it can take up to around three minutes to complete the soldering and there is no temperature, control this can be problematic to some components. Hare is a video of hotplate soldering:

The best way to solder surface mount devices (SMDs) onto printed circuit boards (PCBs) is with a reflow oven, but when that’s not possible, a hot-air station can be successfully used. Hot Air Re-flow Soldering Station is a reliable tool and is not very expensive compared to Re-flow ovens. After thoroughly cleaning the bare PCB with alcohol, the next step is solder application. For the hobbyist, there are two primary methods of applying solder paste to a PCB for surface mount devices: by hand with a syringe or a very small spatula (think wooden toothpick) and by hand with a stencil. After placing the components on the Circuit Board, set the rework station to required temperature and Air Speed. Bring the Nozzle of Blower close to the Circuit board and wait until the Solder paste melts and fuses with the IC Pins.

The challenge is that there are more variables in play when using a hot-air station. In addition to time and temperature, a handheld hot-air gun involves several other factors, including the size of the nozzle, how far the nozzle is held from the solder, the angle of the airflow from the nozzle to the solder, the speed of the air coming from the nozzle, the speed at which the nozzle is moved around over the areas to be soldered. Ideally, the hot-air gun should be held so that the nozzle opening is perpendicular to the surface of the PCB and approximately 12mm (0.5″) above it. Care should be taken to aim the nozzle toward the pins/pads being soldered while avoiding the bodies of the components as much as possible. With a little practice, hot-air soldering is not particularly difficult, but each person must find the balance of temperature, air flow, nozzle size, and gun movement that works for them. As a result of all these variables, hot-air soldering becomes very personalized—each person develops their own “style” of working. Here are some videos:

SMD soldering by hot air (solder paste)

SMD Soldering – Manual Pick And Place – PCB Microscope

Then there is the selection of soldering paste. Solder paste is available in a variety of mixtures of metal. The easiest to use is approximately 60% tin and 40% lead. Alloys commonly used for electrical soldering are 60/40 Sn-Pb, which melts at 188 °C (370 °F), and 63/37 Sn-Pb used principally in electrical/electronic work. This mixture is a eutectic alloy of these metals, which: has the lowest melting point (183 °C or 361 °F) of all the tin-lead alloys. The typical peak re-flow temperatures used for lead solders are in 210 – 220 °C range.

As electronics industry is trying to get rid of lead and moving to lead free solders in may countries. There are many lead-free soldering pastes, but the downside of many of them is that lead-free solder alloys have high melting points as compared to leaded solder and usually somewhat harder to work with. The process temperatures required to solder with tin-based lead-free alloys are challenging for some assemblies. Certain assemblies cannot handle the temperatures used for lead-free soldering which typically reaches 240 – 250 °C. Sensitive components might be damaged by these high temperatures.

For this reasons there are nowadays also special low temperature lead-free solders. Indium and bismuth can be used to lower the melting points of tin-based solders. For example tin/indium 52% and tin/bismuth 58% are lead free solders that have substantially lower melting points than tin / lead 37% solder. The re-flow process temperature for tin / bismuth alloys are low (160 – 170 °C). These low peak temperatures allow for soldering of thermally sensitive assemblies. The temperatures are still high enough, that those solders do not start to melt on most normal electronics applications.

Tin / bismuth solder pastes are readily available from many sources. Generally they are good to use in many applications, but there are few thing to note when working with tin/bismuth alloys. The advantages seem obvious, but somehow the marketing literature does not mention any drawbacks to this type of solder paste. The 42/58 Tin / Bismuth is not unknown as a low temperature solder but has issues. It has reasonable shear strength and fatigue properties, but can be very brittle. Alloys with more than 47% Bi expand upon cooling, which may be used to offset thermal expansion mismatch stresses. The most important thing to note is that combination with lead-tin solder may dramatically lower melting point and lead to joint failure. It is dangerous to mix tin / bismuth with lead containing alloys, because tin, bismuth, and lead can form a very low melting combination that melts around 95 °C. This could potentially lead to solder joint failure due to natural heating of the assembly during use. The good thing is that tin / bismuth alloys are safe to use in combination with other lead free tin-based alloys.

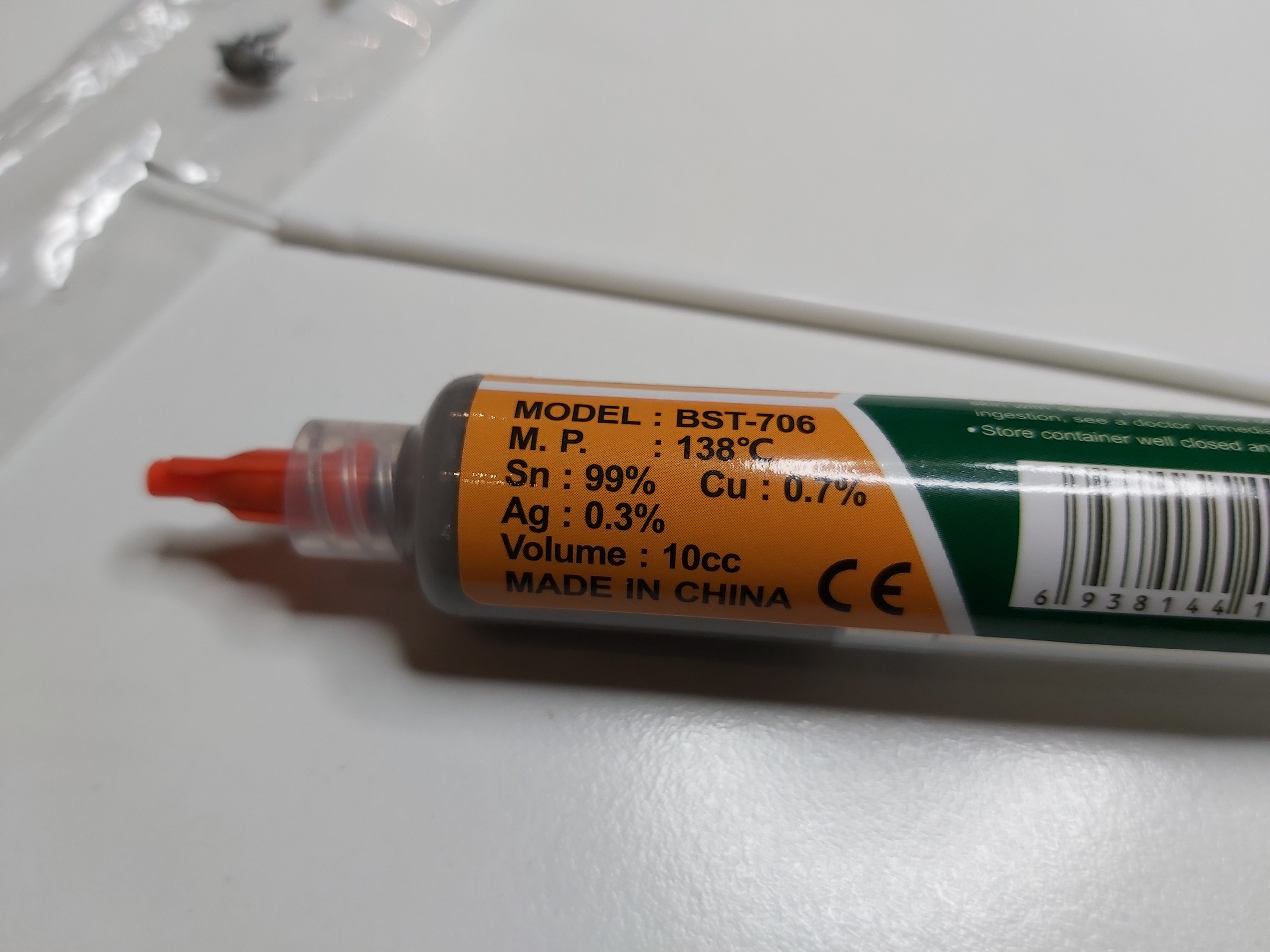

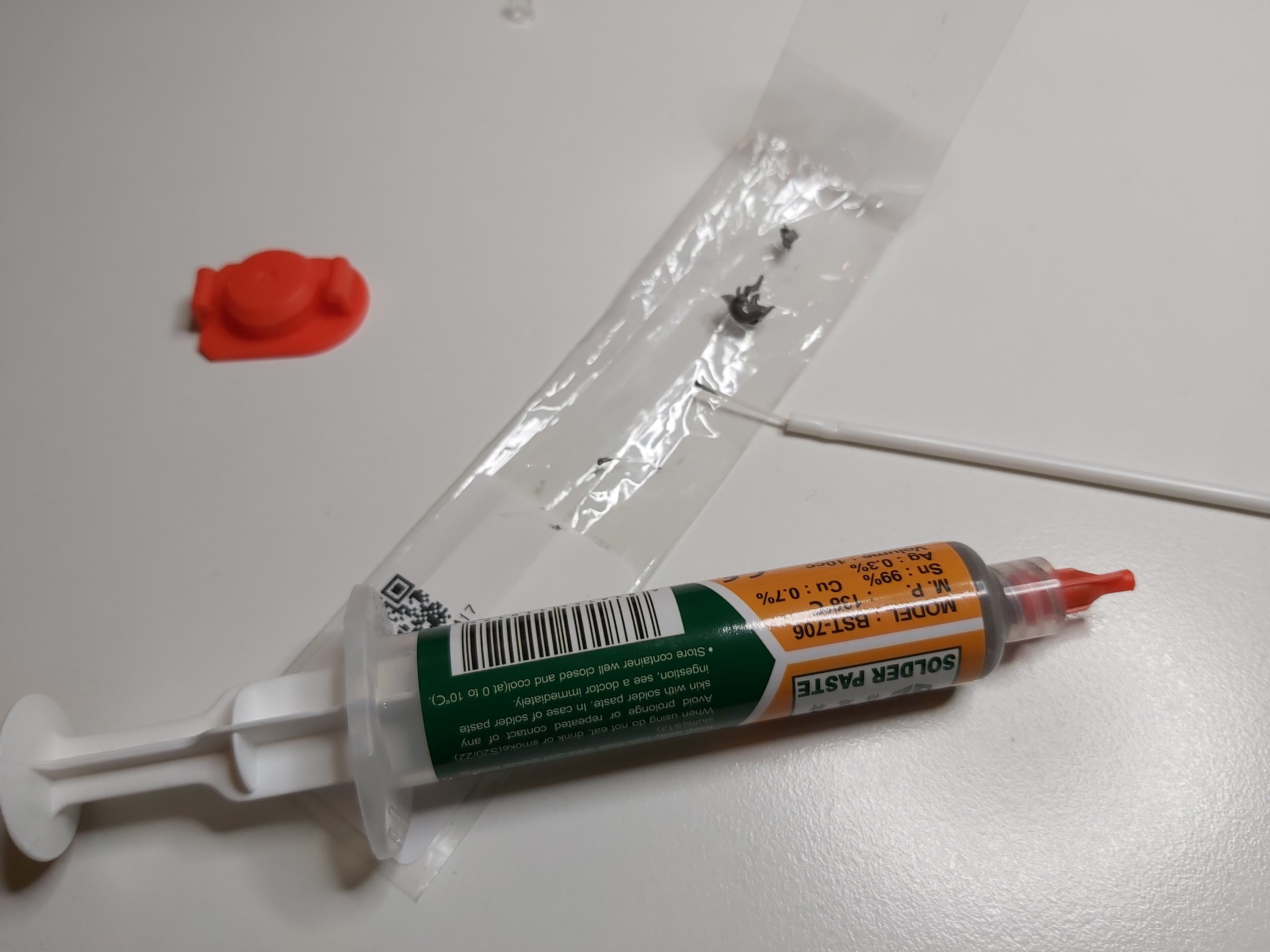

For testing with soldering using low temperature solder flux, I ordered BEST BST-706 10cc 138℃ Syringe DIY Solder Soldering Paste Flux Chips Computer Phone BGA SMD PGA PCB Repair Tool product from Banggood(5.27 Euros). The idea is that with lower process temperature solder I can more easily do DIY SMD soldering without damaging the components.

The product page has this data on this product:

Quanity: 1PCE

Component Sn42/Bi588

Available in syringes

Here is my picture of the product:

This eutectic Sn42 Bi58 solder alloy with a low melting point has been developed for low temperature soldering. With a melting point of 138°C and a peak reflow temperature of approximately 173°C the 670 tin bismuth paste is suitable for soldering of temperature sensitive surface mount components.

The markings on the syringe seems to be somewhat different story than the product page. But it seems that what is said on product page are truthful on the melting temperature. I used an adjustable traditional soldering iron to test the melting temperature, and it was low (melted well at slightly over 150 degrees on test).

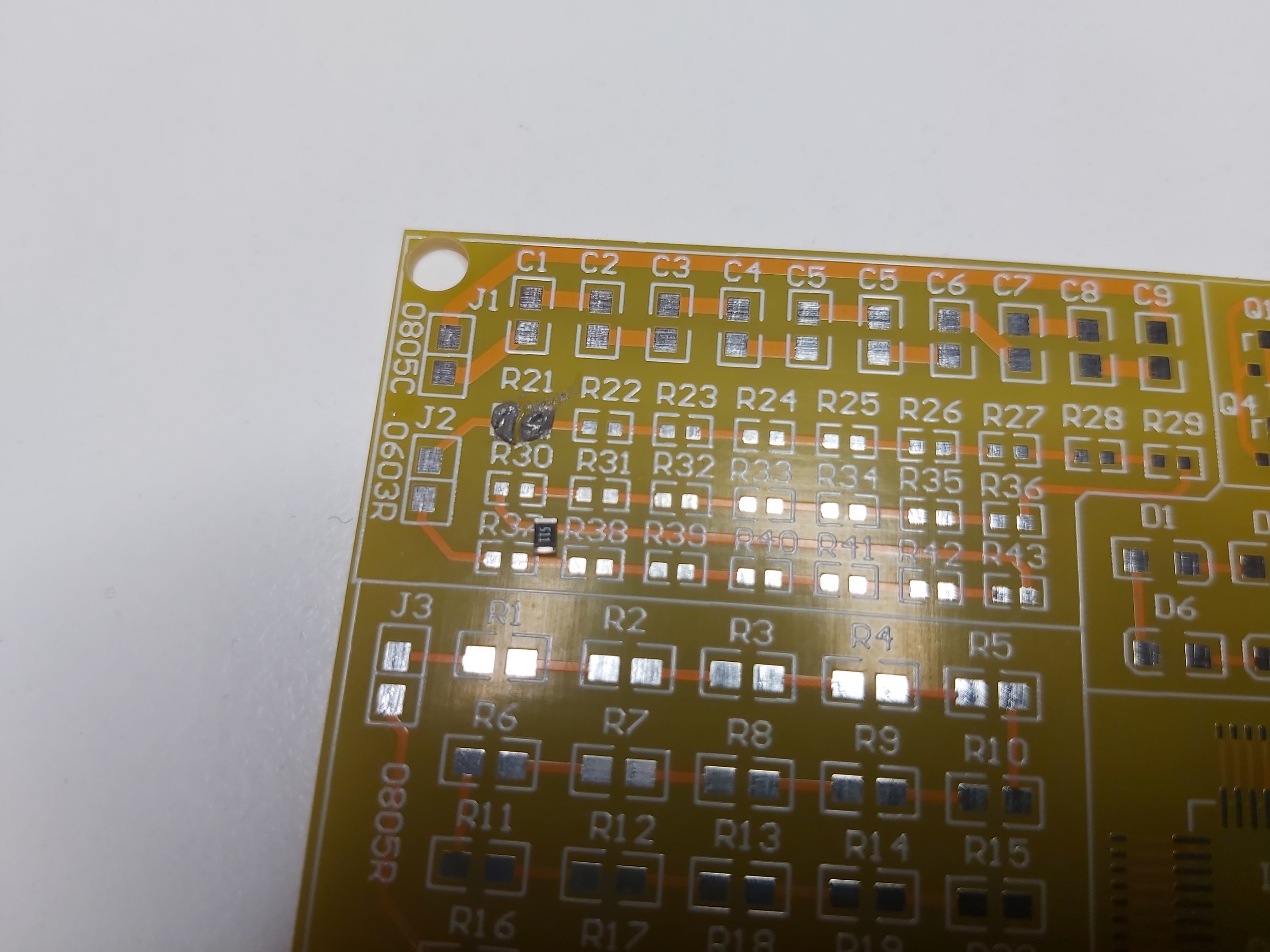

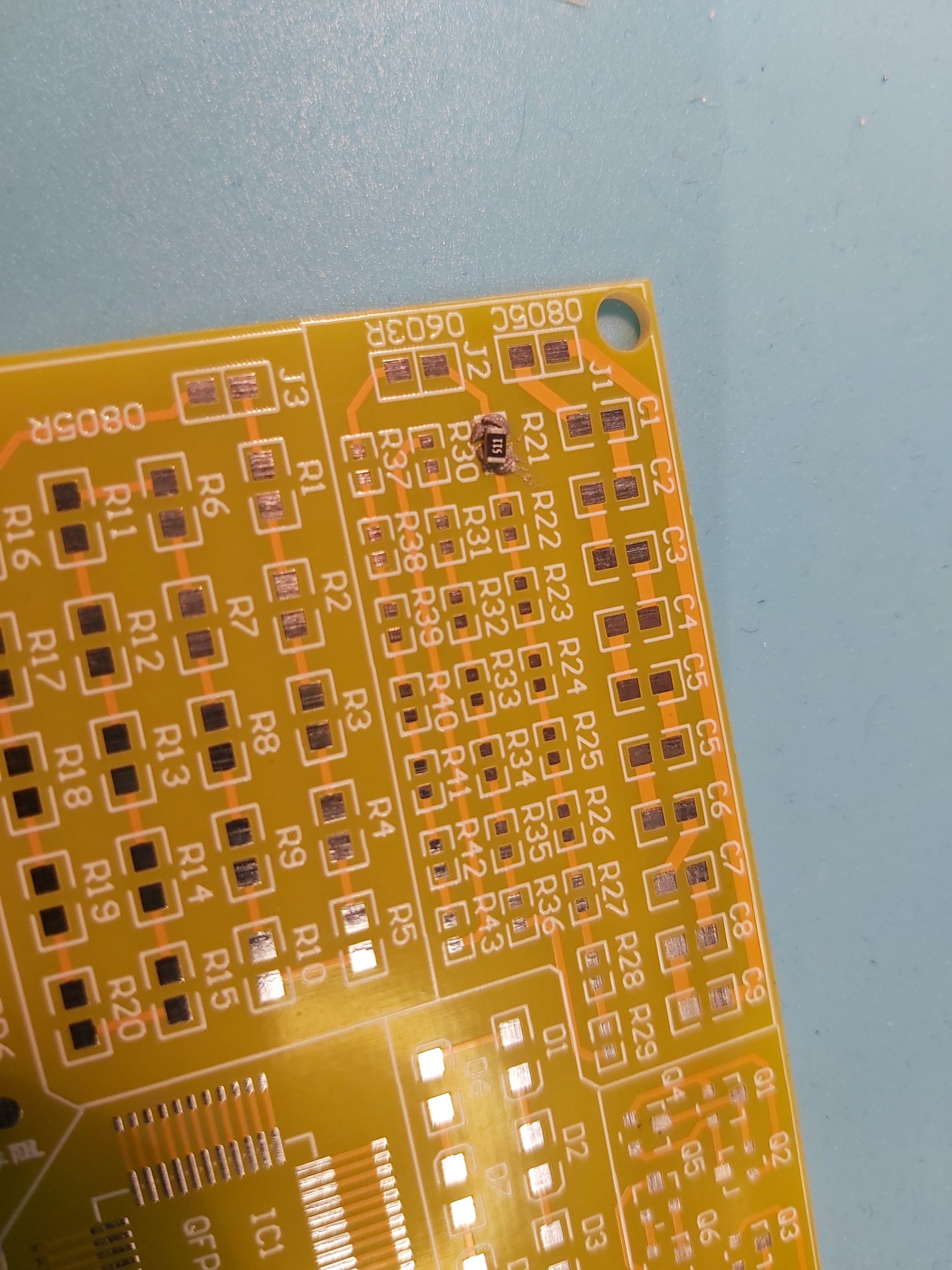

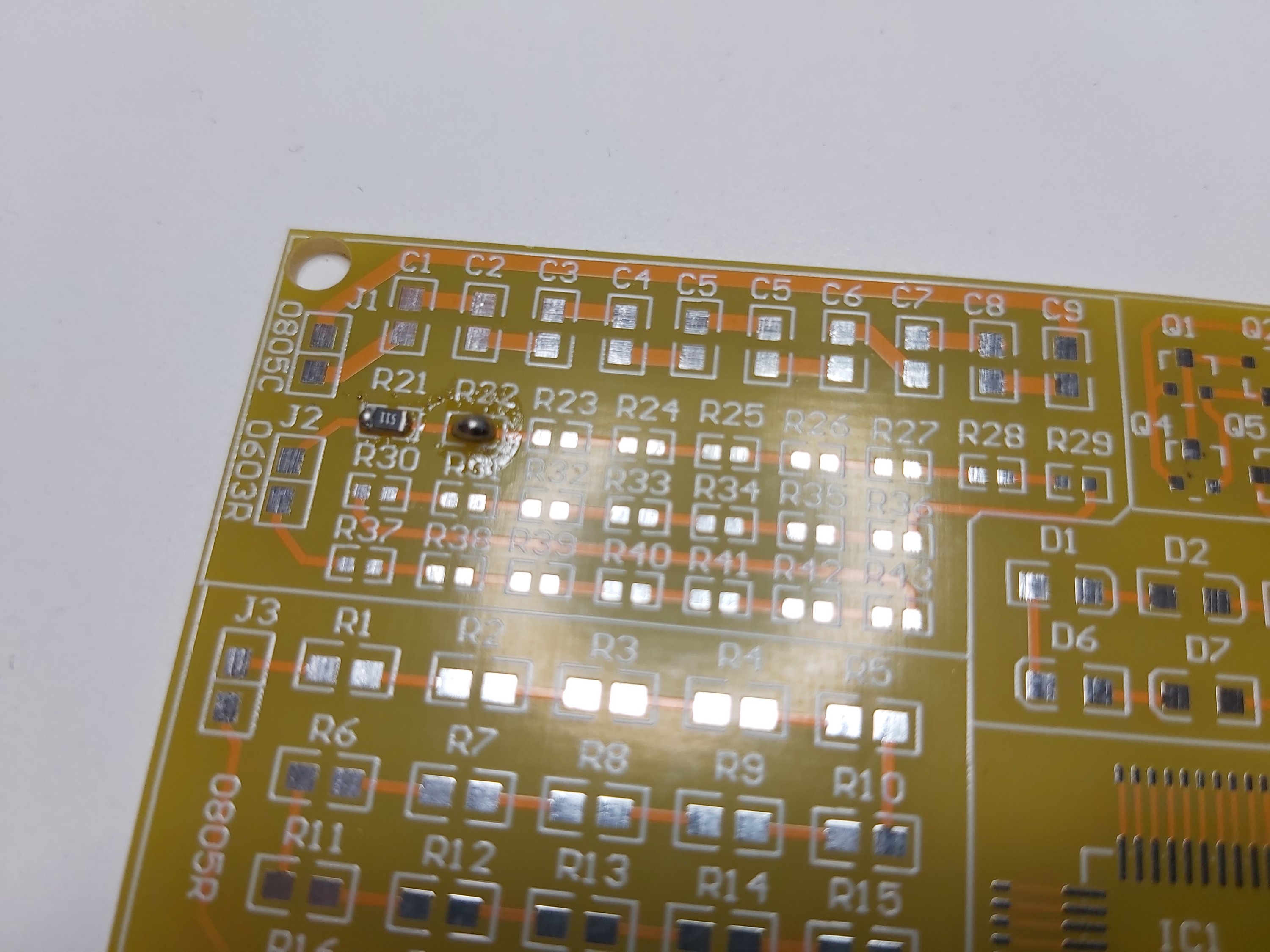

To test how well it works in practice I manually put some soldering paste to the SMD soldering practice board and added component:

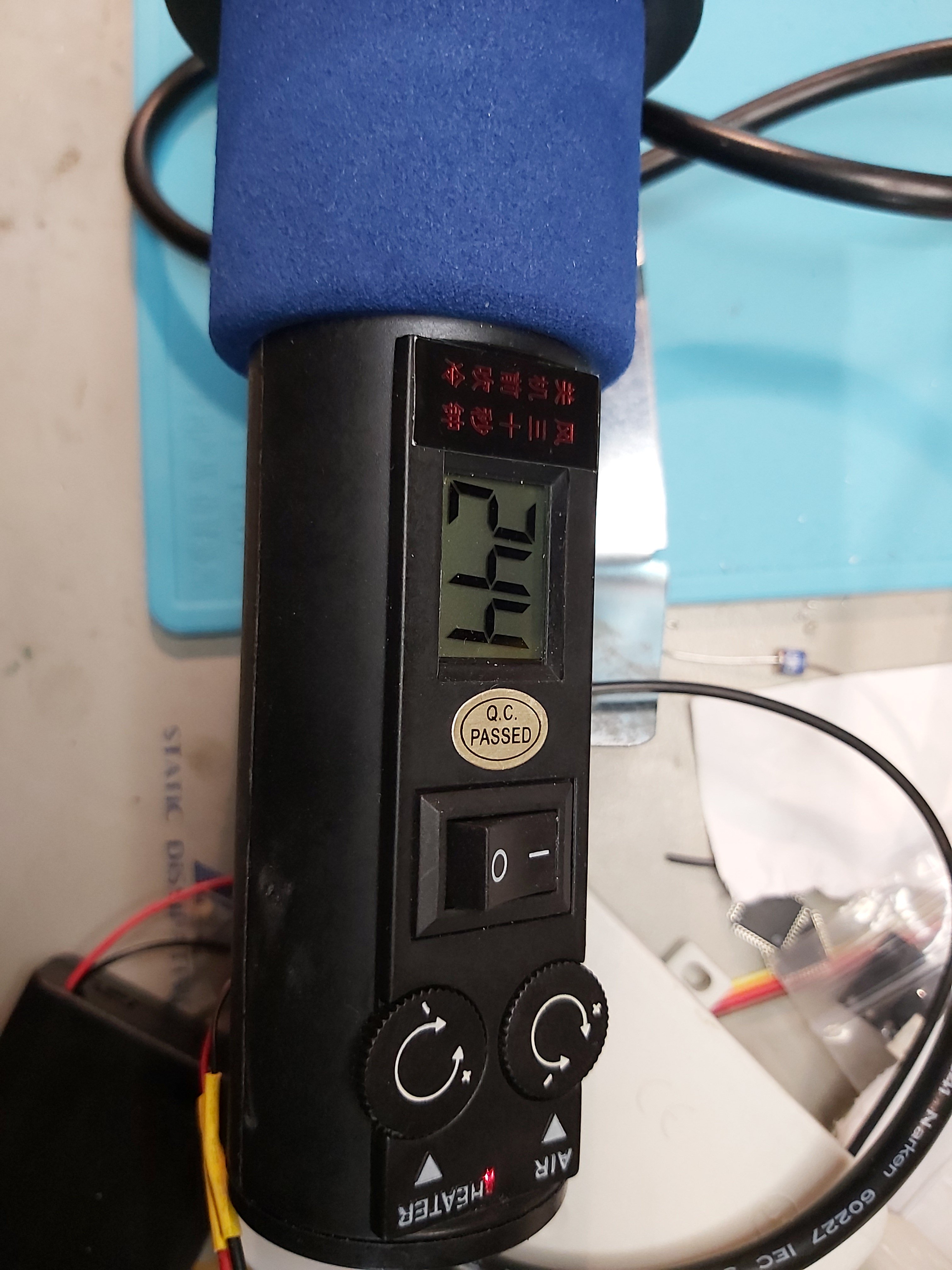

Then I used my soldering heat gun to solder. I used heat temperature of 240-260 degrees Celsius at almost maximum air flow.

With those settings at the way I hold the hot air source it took around 20-30 seconds to melt the tin paste to turn from grey to bright tin color. When I removed the hot air and let it cool, a quite nice soldering joint was made.

This soldering paste seems to work OK as promised.

If you are interested on the product, go to BEST BST-706 10cc 138℃ Syringe DIY Solder Soldering Paste Flux Chips Computer Phone BGA SMD PGA PCB Repair Tool product page or try some other similar product.

22 Comments

Tomi Engdahl says:

https://en.wikipedia.org/wiki/Bismuth

Bismuth is a chemical element with the symbol Bi and atomic number 83. It is a pentavalent post-transition metal and one of the pnictogens with chemical properties resembling its lighter homologs arsenic and antimony.

Bismuth was long considered the element with the highest atomic mass that is stable, but in 2003 it was discovered to be extremely weakly radioactive: its only primordial isotope, bismuth-209, decays via alpha decay with a half-life more than a billion times the estimated age of the universe.

compounds of bismuth are less toxic to humans via ingestion than other heavy metals (lead, arsenic, antimony, etc.)[5] presumably due to the comparatively low solubility of bismuth salts

Bismuth poisoning can occur and has according to some reports been common in relatively recent times.

Bismuth’s environmental impacts are not well known; it may be less likely to bioaccumulate than some other heavy metals

Tomi Engdahl says:

https://en.wikipedia.org/wiki/Indium

Indium is a chemical element with the symbol In and atomic number 49. Indium is the softest metal that is not an alkali metal. It is a silvery-white metal that resembles tin in appearance.

Indium has no biological role, though its compounds are toxic when injected into the bloodstream. Most occupational exposure is through ingestion, from which indium compounds are not absorbed well, and inhalation, from which they are moderately absorbed.

People can be exposed to indium in the workplace by inhalation, ingestion, skin contact, and eye contact. The National Institute for Occupational Safety and Health has set a recommended exposure limit (REL) of 0.1 mg/m3 over an eight-hour workday

Tomi Engdahl says:

PCB Copper Trace Finish: Materials and Plating Methods

https://www.allaboutcircuits.com/technical-articles/pcb-copper-trace-finish-materials-plating-methods/

two essential functions: (1) to protect the exposed copper circuitry, and (2) to provide a solderable surface when assembling (soldering) components to the PCB. A variety of PCB copper plating options exist, and each carries its own advantages and disadvantages.

HASL

Hot air solder leveling (HASL), is known as the tried-and-true copper plating method. This process works by dipping a board in molten solder and then leveling it off with a hot air knife, hence its name.

HASL is known for being the least expensive type of PCB surface finish

might run into problems if your board uses either SOIC or small SMT components.

Some other disadvantages include having uneven surfaces, possible solder bridging, plugged or reduced plated through-holes, and, of course, HASL uses lead, so this option isn’t viable for projects requiring RoHS-compliance. If your project does indeed require RoHS-compliance, you might need to consider using lead-free HASL.

Immersion Tin

Immersion coating methods utilize a chemical process for depositing a flat metal layer directly on the copper traces. Besides providing a flat surface for parts to be soldered to, tin immersion does not require the use of lead; therefore, this process yields a RoHS-compliant PCB surface. Unfortunately, the use of tin allows for the possibility of tin whiskers

OSP

OSP (Organic Solderability Preservative) is a process that protects the copper surface from oxidation.

ENIG

The ENIG (Electroless Nickel Immersion Gold) finish has historically been the best fine-pitch (flat) surface and lead-free option worldwide

ENIG is a two-step process that layers a thin coating of gold over a thin coating of nickel.

Hard Gold

Hard gold, technically known as hard electrolytic gold, consists of a layer of gold plated over a coating of nickel.

Carbon Ink

Using carbon ink in place of hard gold is an option that offers lower costs and high robustness.

Tomi Engdahl says:

Lead-Free Solder Alloys: Their Properties And Best Types For Daily Use

https://hackaday.com/2020/01/28/lead-free-solder-alloys-their-properties-and-best-types-for-daily-use/

BETTY HUNT says:

Information is really very helpful. The application of soldering paste at right temperature is really very crucial.

Tomi Engdahl says:

SMD Soldering Tutorial | Guide | Tools | Tecniques | Stencil

https://www.youtube.com/watch?v=fYInlAmPnGo

In this video I show you a few tecniques for soldering SMD components. We start easy with two pins components of size 1206, 0805, 0603 and 0402. Then some SOT23 and some SOP8 and SOP16. We also solder microcontroller, QFN chip with soldering stencil and solder paste and the hot air gun.

Tomi Engdahl says:

PTC Heating Plate For Desoldering LED Lamp beads BGA,Thermostat Heater Welding Soldering Plate

https://www.youtube.com/watch?v=l3izspTesyw

Tomi Engdahl says:

However, if contaminated with lead, tin-bismuth solders can produce a eutectic phase that melts at 96C. In such situations the resulting solder joint exhibits poor performance in thermal cycle testing.

Tomi Engdahl says:

https://www.indium.com/blog/has-the-time-come-for-tin-bismuth-solders.php

Tomi Engdahl says:

https://www.materialshub.com/material/bismuth-tin-lump/

Tomi Engdahl says:

https://www.belmontmetals.com/bismuth-alloy-leadalternative/

Tomi Engdahl says:

Reflow Soldering of Chip Capacitor – Surface Mount Process

https://www.youtube.com/watch?v=VMyd0ydGNMA

REFLOW SOLDERING PROCESS

https://www.surfacemountprocess.com/reflow-soldering-process.html

Tomi Engdahl says:

Solder Paste Type Comparison – Surface Mount Process

https://www.youtube.com/watch?v=dwTAi1KSfMQ

Choosing which type of solder paste to use can be a challenge and understanding the difference will be useful to make the decision. For some time type 3 used to be the industry standard but more recently type 4 is more widely used in solder paste printing – For more details see

https://www.surfacemountprocess.com/solder-paste-printing-process.html

Tomi Engdahl says:

https://www.hackster.io/john-bradnam/pcb-reflow-hot-plate-ad6726

Tomi Engdahl says:

SMD prototype soldering

https://www.youtube.com/shorts/5Qiru_fqdj8

Tomi Engdahl says:

Ihmiset kysyvät myös

Is bismuth less toxic than lead?

The substitution of lead with bismuth in the manufacturing industry has drawn growing attention recently in terms of resolving environmental problems caused by heavy metal pollution because bismuth shares many characteristics of lead but is much less toxic to living organisms.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7151860/

Tomi Engdahl says:

Bismuth alloy can be a safer, non-toxic alternative, the look of it can also vary depending upon the processing. Consuming any amount of lead can have adverse effects, whereas bismuth compounds are insoluble and cannot be easily absorbed into the body, making heavy metal poisoning much less likely

https://www.thebismuthsmith.com/bismuth-lures-sinkers-and-bullets-oh-my/

Tomi Engdahl says:

Why is bismuth less toxic?

Elemental bismuth is nontoxic, but bismuth salts can cause toxicity. Bismuth salts are relatively insoluble, so environmental and occupational exposure is low. Most toxic exposure to bismuth is from consumption, usually from medicinal use.10.6.2019

https://u.osu.edu/helmig-mason.1/2019/06/10/bismuth-heavy-metal-toxicity/

Tomi Engdahl says:

The European Union’s Restriction of Hazardous Substances Directive (RoHS) for reduction of lead has broadened bismuth’s use in electronics as a component of …

https://en.m.wikipedia.org/wiki/Bismuth

Tomi Engdahl says:

Is bismuth RoHS compliant?

When thermal exposure during the assembly process is a limitation, NC273LT solder paste for bismuth bearing alloys is an excellent RoHS compliant replacement. Bismuth bearing solder pastes can reduce peak reflow temperature requirements to as low as 170°C – 175°C (340°F – 350°F).

https://aimsolder.com/products/solder-paste/nc273lt-low-temperature-solder-paste

Tomi Engdahl says:

Is bismuth as toxic as lead?

The substitution of lead with bismuth in the manufacturing industry has drawn growing attention recently in terms of resolving environmental problems caused by heavy metal pollution because bismuth shares many characteristics of lead but is much less toxic to living organisms.

https://www.ncbi.nlm.nih.gov/pmc/articles/PMC7151860/

John Kek says:

This article is one of the best of the whole internet https://www.epanorama.net/blog/2019/12/15/low-temperature-smd-soldering-paste/